ROV

ROV

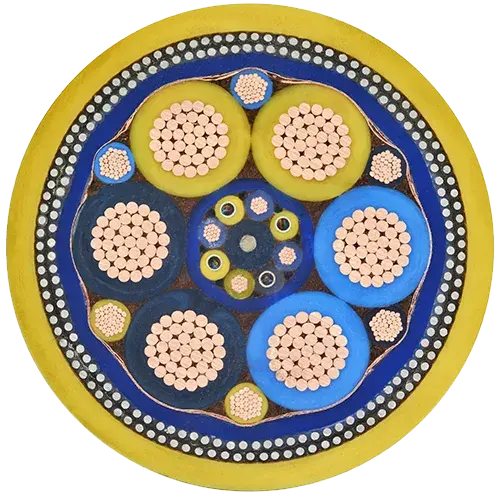

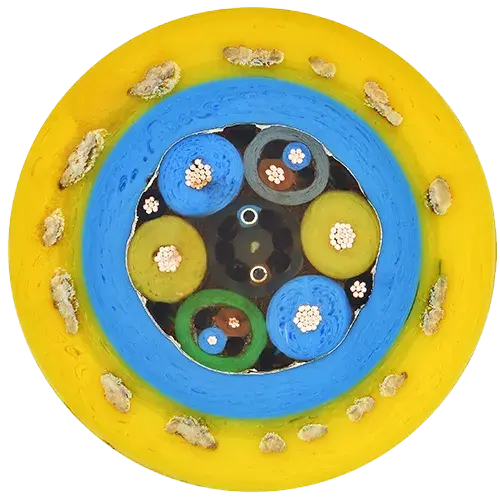

Cable solutions for Remotely Operated Vehicles

Cable solutions for Remotely Operated Vehicles

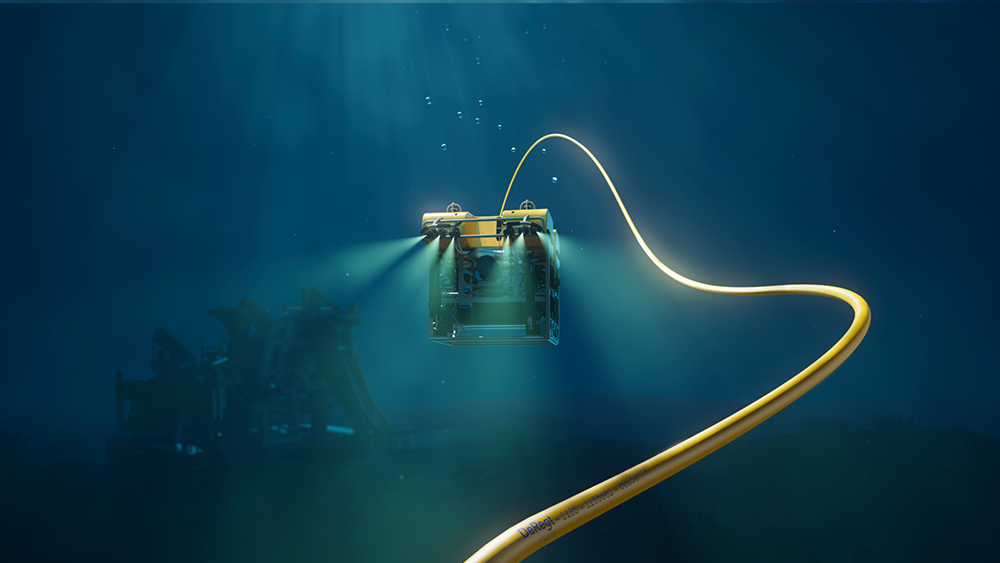

For ROVs, operating where the ocean sets the most demanding conditions, reliability can’t be left to chance. Here, DeRegt’s solutions safeguard perfect control.

ROV operations demand more than catalog cables. Weight, buoyancy, diameter, integration, every detail matters. That’s why we design with you, not for you. Together, we optimize performance, prevent down-time, and build an umbilical proven to perform in the field.

--:--

Discover how DeRegt's custom cable solutions can meet your unique requirements. Whether you need cables for short or long distances, our experts are here to help you every step of the way.

Hanieh Shamsizadeh

Business development manager ROV

Call +31 (0) 643204122