As an engineer in the defense market, you often have to deal with customers with many specifications and requirements. Many of these requirements have to flow down on the different components of your project – like in the (sonar) cable.

Often, this involves looking at international norms, standards and MIL-SPECs. If you need to know about all these requirements, you will have to go through a lot of research.

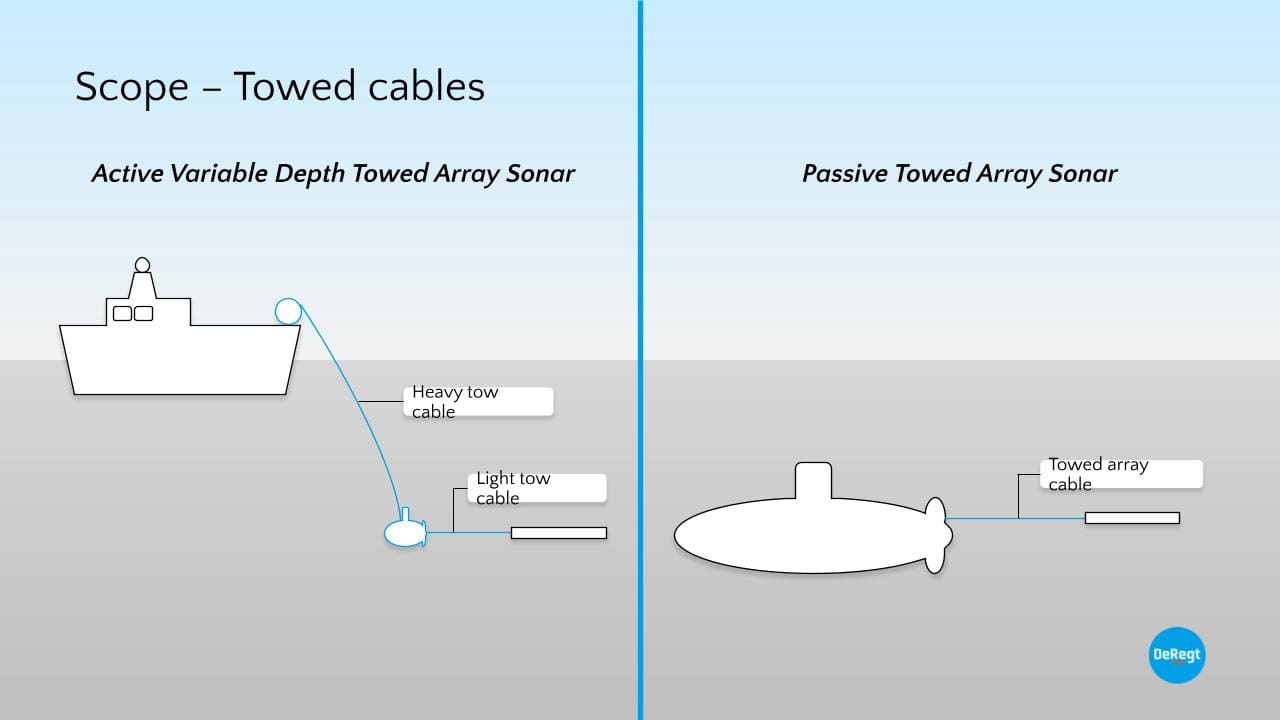

Don’t worry, as an engineer you don’t need to know everything about every single component. After all, you have partners who can help you with this and know all the MIL-SPECs for their components. On this page, we look at various cable solutions for naval systems and you will find information about specifications, testing, and validation of these cables.